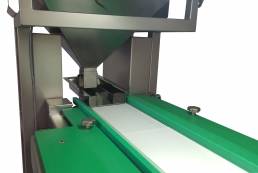

INSPECTION TABLES

The equipments are used for sorting and manually removing non-compliant capsules.

Affordable and loaded with features, on a stable, height adjustable, massive stainless steel frame are located the following components:

-Feeding hopper. In order to maintain the optimal supply level of capsules, the hopper’s tray is endowed with a vibrating unit controlled through a variable frequency drive.

-Belt Conveyor, moved by electric gearmotor controlled through a variable frequency drive.

-Belt tensioner

-6 mm float glass deck

-Upper LED lighting

-Lower LED contrast lighting

-PE 1000 handrails

-Pedal air-operated tilting discharging chute

-Main electric cabinet with general I/O switch

-Control panel with vibrating unit and belt speed I/O switch and potentiometers, upper and lower lighting I/O switch, emergency mushroom.

-Briefcase housings

The metallic structures is entirely executed in stainless steel (AISI 304/AISI 316), as well as all the mechanical and fastening components. Ozone and UV-resistant premium food-grade belting material.

The metallic parts not in contact with the products are glass blasted while the parts in contact with the capsules (interior surface of the hopper and of the discharging chute) are polished with successively finer abrasives obtaining a very smooth surface (roughness < 0,4 μm) assuring minimal friction and optimum cleanability of the surfaces.

The 3D design in all its details allows the perfect reproducibility of the whole equipment or of its smaller spare part.

Model ST3000

Power: AC 380 V

Frequency: 50 Hz

Power Consumption: 0,32 Kw

Overall dimensions: LWH 2.880 x 670 x 1.580 mm

METALLINA is in a position to design, detail and manufacture tailor-made inspection tables, meeting our customers’ needs and specifications

Adress

Str. Prof. Dr. Aurel Ardelean, 26

310059 ARAD

Romania

Registration

Arad County Commerce Register

J2/1782/1991

EU VAT nr

RO1693649

Phone

+40257 280 838